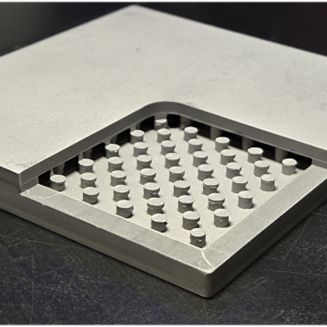

Metal Matrix Composites

Silicon Carbide Reinforced Aluminum for Thermal Management

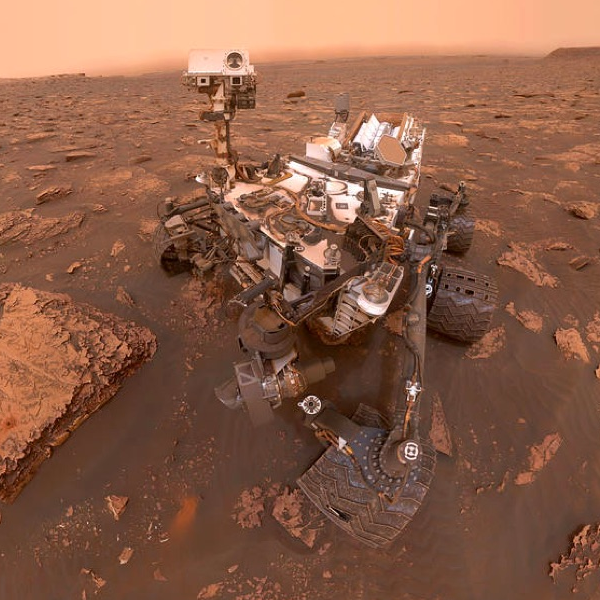

Metal Matrix Composites combine robust mechanical performance with high-temperature compatibility and low density to meet the needs of emerging technologies, such as high voltage DC transmission and hybrid electric powertrains, while outshining monolithic material alternatives.

180

Ideal for heat dissipating structures

<10

Ensuring dimensional stability across a range of temperatures

3

Ideal for projects concerning weight

180

High stiffness materials for robust performance

What Makes Our Metal Matrix Composites Superior

Aluminum Silicon Carbide (AlSiC) Metal Matrix Composites (MMCs) from CPS combine the best properties of various materials, outperforming traditional solutions in various applications

Improved Strength and Stiffness

MMCs combine the best properties of metals & ceramics, allowing for structural performance not observed in monolithic solutions.

Decreased Thermal Expansion

Tailorable, low coefficient of thermal expansion values allow for MMC compatibility in applications with extreme heat, extreme cold, or broad temperature swings.

Lightweight

With a comparable density to aluminum alloys and improved performance characteristics, our MMCs enable our customers to achieve the performance they require with a reduced weight profile.

Review Our Spec Sheet

Want more information on what makes CPS metal matrix composites the best in the world? Check our spec sheet for details.

Contact Our Team

CPS engineers are eager to create the MMC solutions your project needs. Contact us to learn more.