Founded in 1984, CPS Technologies Corp. has long been a leader in providing metal matrix composite (MMC) solutions. Over the last 40 years, CPS has introduced new product lines, including hermetic packages in 2005 and HybridTech Armor in 2012, and new manufacturing processes to provide the most value to our customers. 2025 will be no different, as CPS has been hard at work over the past year designing, developing, and manufacturing new materials to solve a new generation of material science challenges, and investing in state of the art production processes to meet our customers’ needs.

Fiber Reinforced Composites for Structural Applications

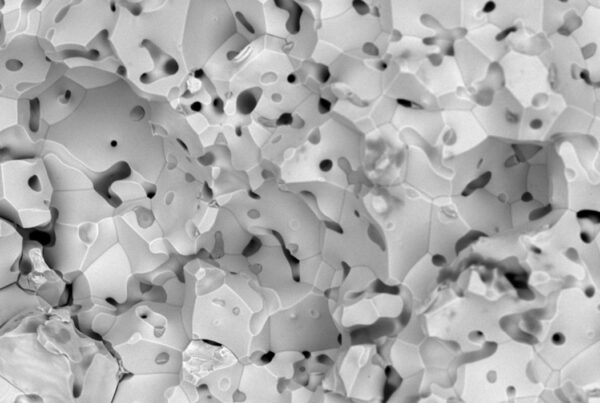

Through a licensing agreement with Triton Systems, CPS acquired the exclusive rights to manufacture and sell Fiber-Reinforced Aluminum (FRA) ®. By discontinuously reinforcing high strength aluminum alloys with short ceramic fibers, FRA offers superior wear-resistance, increased aluminum service temperatures, and isotropic mechanical and physical properties. With these unique properties, the patented FRA material system has a multitude of applications in military vehicles (fixed-wing, helicopters, tilt rotor, UAVs, and combat vehicles) and commercial markets (aerospace, motor sports, heavy trucks, and oilfield drilling).

CPS Technologies is working on a variety of MMC solutions, reinforcing aluminums with continuous and discontinuous ceramic fibers for applications including, but not limited to:

- Propulsion System Components

- Landing Gear and other Struts

- Fire Barriers and Thermal Protection Systems

- Brake Rotors and Bearings

- High Temperature Fiber Wound Cylinders

Particle Reinforced Materials for Thermal and Radiation Management

Thermal Energy Storage using Phase Change Materials

For the last three years CPS has been working with the US Navy under the SBIR program to develop a new solution for thermal energy storage in the Advanced Anti-Radiation Guided Missile – Extended Range (AARGM-ER) system. In June of last year, CPS was awarded a Phase II SBIR to continue this work.

During Phase I efforts, CPS demonstrated the use of aluminum and phase-change materials, such as nickel titanium (or nitinol), for compact thermal energy storage devices, specifically for the AARGM-ER. This work will continue in 2025 with Phase II, as CPS evaluates materials and processes by which a net shape part can be produced to replace traditional solid to liquid solutions.

Upon successful completion, in addition to supporting the AARGM-ER program, CPS will leverage the aluminum-nickel titanium (Al-NiTi) composites for relevant aerospace, defense, and automotive applications. The primary benefit of this solution is the removal of liquids that are difficult to contain after melting, and the integration of thermal energy storage into the structure of the system itself thus reducing complexity and weight.

Radiation Shielding

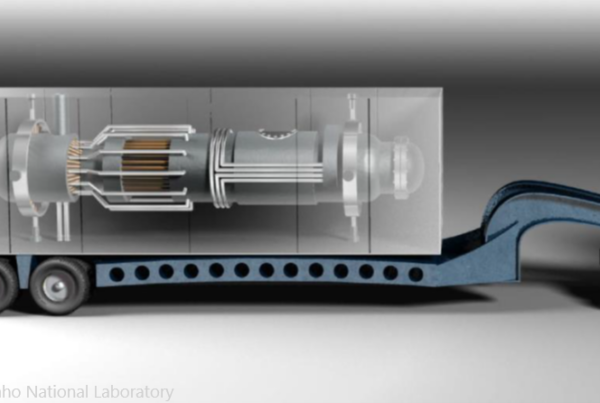

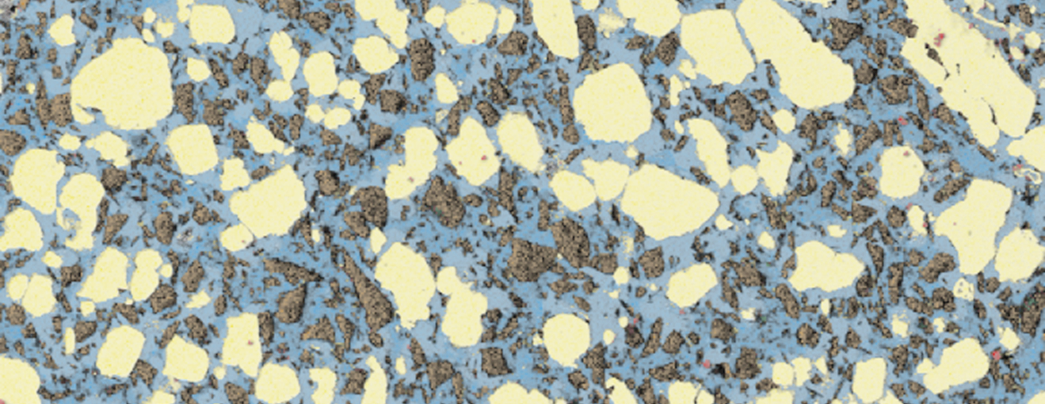

In September, CPS received a second Phase II SBIR from the Department of Energy, providing funding to further explore “Modular Radiation Shielding for Transportation and Use of Microreactors.” During Phase I of this SBIR, CPS was able to demonstrate that utilizing multiple reinforcements within a single MMC mitigates gamma and neutron radiation while driving down overall system mass by as much as 50%.

The Phase II research will focus on developing real world solutions based on feedback from industry on performance requirements of new reactor designs.

Investing to Support Future Needs

For most of its history, CPS Technologies has relied on 3-axis CNC machining, with more complicated requirements being outsourced. This all changed in 2024 as CPS, with the help of a MassMEP grant, was able to purchase and install a 5-axis CNC machine at our facility in Norton, MA. With this acquisition, CPS is now capable of machining complex components completely in house reducing costs and delivery time. The new 5-axis CNC not only expands our product offerings in the Hermetic Package market, but also lays the foundation for delivering build to print components machined from the new materials that are being developed by our team.

CPS Technologies is the Premier Composite Partner

CPS Technologies is a trusted industry leader in metal matrix composites and hermetic packaging. Our team of engineers, research scientists, and manufacturing experts is driven to improve our manufacturing process and design new materials for modern problems.

With CPS Technologies as a partner, you can leverage our extensive expertise and knowledge to solve the challenges of today’s world. Contact a metal matrix composite specialist today to get started!

Global Innovation at CPS Technologies

Ready to discuss your MMC design needs?

CPS offers a suite of innovative solutions to give clients complete peace of mind in their solution. With our state-of-the-art AlSiC composite, proprietary machining processes, and time-tested expertise, we’ll show you why CPS is a trusted partner in the industry.