Titanium (Ti) alloys are synonymous with high performance in the most demanding industries, particularly aerospace applications. Titanium is applied in critical areas where high strength and low weight are required, due to the fact it is as strong as steel, while being 40% lighter, and offers excellent fracture toughness. At elevated temperatures it excels, retaining a high tensile strength, showing a strong resistance to creep, and a resistance to corrosion. Titanium also significantly outperforms typical aluminum alloys in both strength and stiffness. Aircraft leverage titanium in airframe components, include wing spars and fuselage structures, and engines, utilizing titanium for fan blades and shafts. Additional support structures such as landing gear, fasteners, and seat rails are also often made from titanium alloys.

While titanium is a highly desirable material, there are several challenges with using it in the current geopolitical environment, including cost and sourcing concerns. Because of these drawbacks, many companies that have traditionally used titanium are actively looking for an alternative.

Drawbacks to Titanium

Cost

Titanium is an extremely expensive material to produce. Refining titanium ore can cost upwards of $8,000 per ton. A majority of ilmenite and rutile deposits, from which titanium ore is produced, are outside of the US and Europe, leading to costly imports of raw material or refined titanium. Additionally, the properties that make this such a desired material, such as strength and temperature resistance, also make it very difficult and costly to work with once it has been imported.

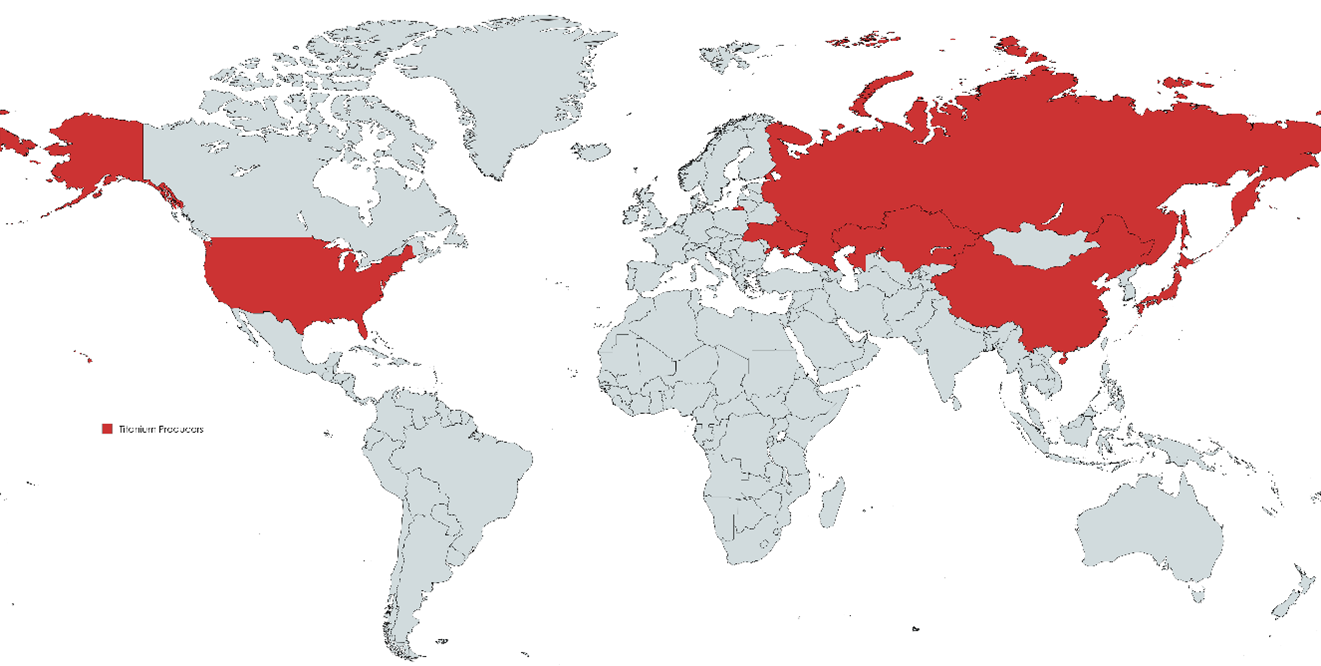

Supply Chain Issues

While there are many facilities around the world where titanium can be manufactured, the largest producer in the world, VSMPO-AVISMA, is a Russian company, with other producers primarily being found in Ukraine, Japan, and China. As geopolitical tensions rise, supply chain disruptions have continued to complicate material sourcing. These disruptions make the already costly material more expensive, or unavailable entirely. Given these issues, what are the alternatives?

Materials to Replace Titanium

There are traditional structural alloys that share some properties with titanium, but none meet the full set of requirements with comparable cost and manufacturability. Steel alloys, while extremely strong and durable, are far too dense for most aerospace applications. Aluminum is used wherever possible in aerospace designs as it is lightweight and relatively corrosion-resistant, but the increased strength, stiffness, and operating temperatures offered by titanium usually win out. Enhancing these characteristics in aluminum alloys would help reduce the dependence on foreign titanium, while offering a cheaper alternative.

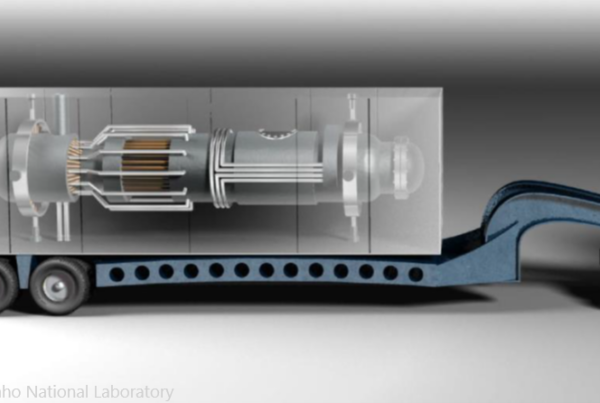

With these design considerations in mind, the CPS Technologies team is actively investing in advanced research and development to bridge the performance gap between unreinforced aluminum and titanium by using metal matrix composites (MMCs). CPS is developing fiber reinforced aluminum to provide lightweight materials that exceed the performance of traditional structural alloys such as titanium.

Benefits of Fiber Reinforced Aluminum

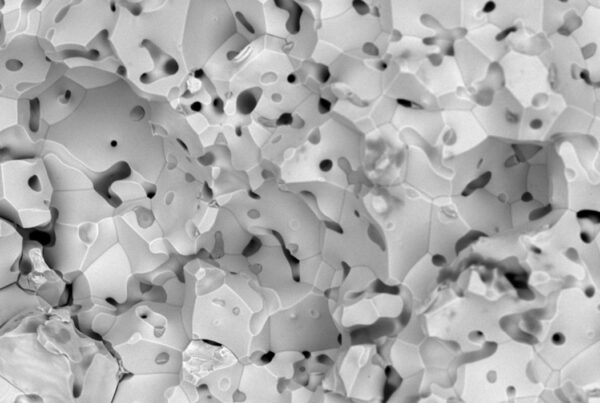

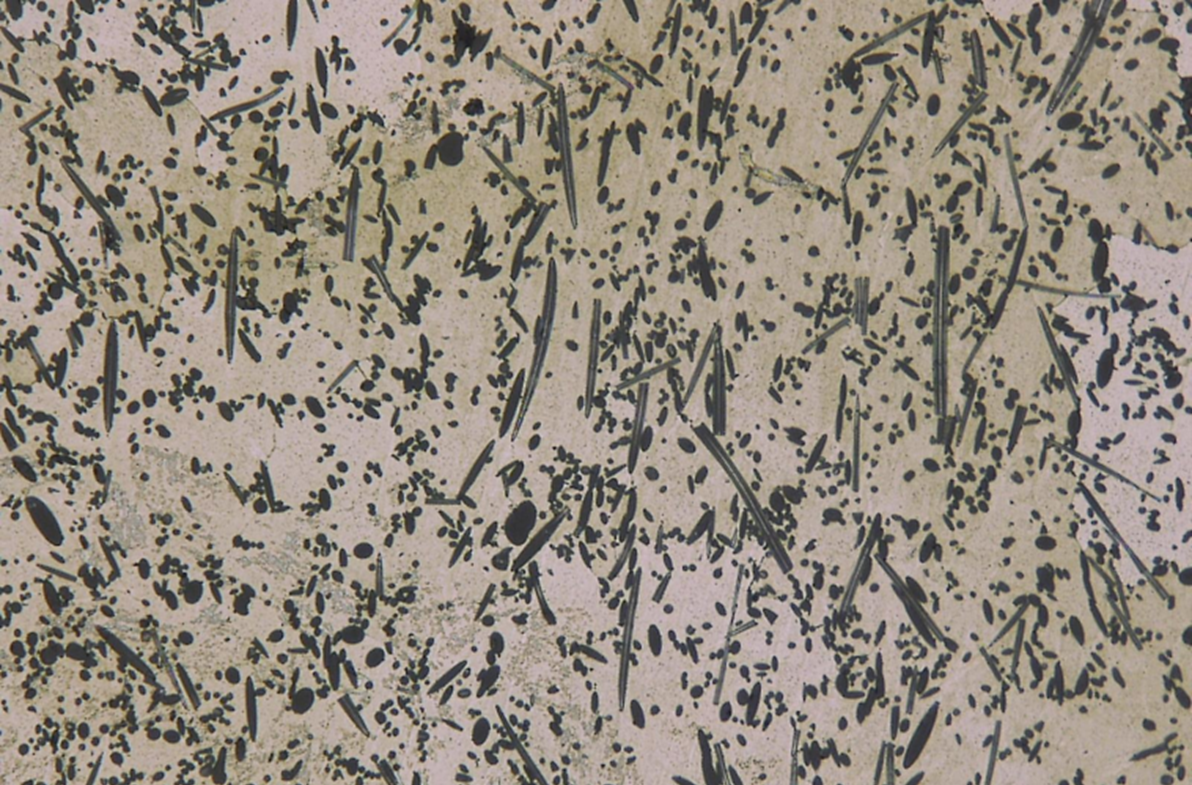

Created by combining discontinuous ceramic fibers and aluminum, Fiber Reinforced Aluminum (FRA) metal matrix composite materials offer improved thermal, mechanical, and wear performance over traditional aluminum alloys and composites. The benefits of FRA manufactured by CPS lends itself to a multitude of both military and commercial applications, creating a stronger, more reliable product. Benefits include:

- Sustained mechanical performance above 400°F: FRA keeps performing in harsh environments by maintaining 3x the strength of conventional aluminum alloys at elevated temperatures. FRA maintains a tensile modulus of 83 GPa at 400°F, allowing it to be implemented in thermomechanical systems where traditional Al alloys cannot be considered. FRA has been evaluated for mechanical performance following extended exposure to high temperatures (6000 hours at 350°F) showing minimal drop in tensile strength compared to unreinforced aluminum alloys.

- Improved wear resistance: While operating at higher temperatures, FRA also shows an increased durability over time. Fiber Reinforced Aluminum has a 200% improved wear resistance compared to steel or cast iron.

- Low density: FRA has a density of 2.96 g/cm3 making it ~30% lighter than titanium while only being 10% heavier than neat aluminum.

- Workability: FRA is machinable, forgeable, and weldable, allowing companies to get products they need without the extra hassle titanium brings from high temperature forging. In addition, CPS is actively working on developing processes to net shape injection mold FRA composites, further reducing the machining required

CPS Technologies is the Premier Composite Partner

CPS Technologies is a trusted industry leader in metal matrix composites and hermetic packaging. Our team of engineers, research scientists, and manufacturing experts is driven to improve our manufacturing process and design new materials for modern problems.

With CPS Technologies as a partner, you can leverage our extensive expertise and knowledge to solve the challenges of today’s world. Contact a metal matrix composite specialist today to get started!

Global Innovation at CPS Technologies

Ready to discuss your MMC design needs?

CPS offers a suite of innovative solutions to give clients complete peace of mind in their solution. With our state-of-the-art AlSiC composite, proprietary machining processes, and time-tested expertise, we’ll show you why CPS is a trusted partner in the industry.