Advanced material solutions are what CPS Technologies does best. We are well-known for our expertise in the design, development, and manufacturing of metallic and ceramic-based Metal Matrix Composites (MMCs). These MMCs continue to impress our clients, enhance operational capabilities, and improve the industries within which we operate.

The unique properties MMCs provide combined with an innovative approach to solving traditional material challenges make our materials perfect for modern military applications, including, cutting-edge armor that provides a lightweight alternative to legacy ballistic materials while maintaining the highest levels of performance.

Modern Metal Matrix Composite Solutions

Metal Matrix Composites combine a metallic base with reinforcing ceramics to yield unique performance characteristics that surpass those of traditional monolithic solutions.

At CPS, we have decades of experience combining various materials and ceramics to support our customers’ needs. Our proprietary manufacturing processes allow us to manufacture, at scale, large-volume composite parts. CPS composite solutions are used around the world to solve the toughest thermal, structural, and ballistic challenges. CPS materials are used in the aerospace, defense, industrial, energy, and transportation industries.

Ongoing Military Armor Challenges

The same material objectives have persisted throughout most of modern military history: maximum protection, maximum mobility, and maximum operational capability and readiness. The material scientists capable of designing, producing, and perfecting solutions to these challenges help propel defense technology forward.

As conflicts evolve, one of the biggest challenges facing militaries is dependable maneuverability on the battlefield. While maneuverability becomes more and more important, it creates new challenges for CPS to solve.

Common challenges facing survivability modernization programs include:

- Ballistic protection – Armor that effectively withstands a wide range of ballistic threats.

- Weight reduction – Armor that reduces the weight of systems to enhance mobility and efficiency without compromising protection.

- Interoperability – Armor that allows greater integration of functionalities like thermal management, situational awareness technologies, and communication systems.

- Adaptability – Armor that adapts to different combat environments while maintaining optimal protection.

- Cost-efficiency – Armor systems that balance the cost of materials with lifecycle cost savings.

- Maintenance and durability – Armor that ensures systems are durable, resistant to wear and tear, and can be easily maintained in the field without compromising protective capabilities.

CPS has spent over 30 years developing solutions to challenges like the ones modern militaries face. Over this time, CPS has found ways to overcome these obstacles to provide enhanced protection and survivability for military personnel in complex and dynamic operational environments.

CPS MMCs Provide an Alternative to Legacy Approaches

High hard steel is a specialized alloy engineered to provide exceptional hardness and ballistic protection for military vehicles and personnel. For these reasons, it has historically been the material of choice for modern military defense applications that require heavy ballistic protection. Unfortunately, steel’s density is considerable, negatively impacting vehicle mobility, operational readiness, and total life cycle cost.

Metal Matrix Composites (MMCs) are perfect candidates to replace legacy solutions like steel, providing similar performance at fractions of the weight.

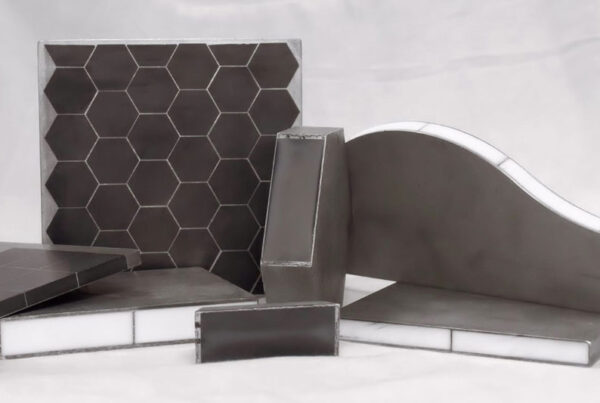

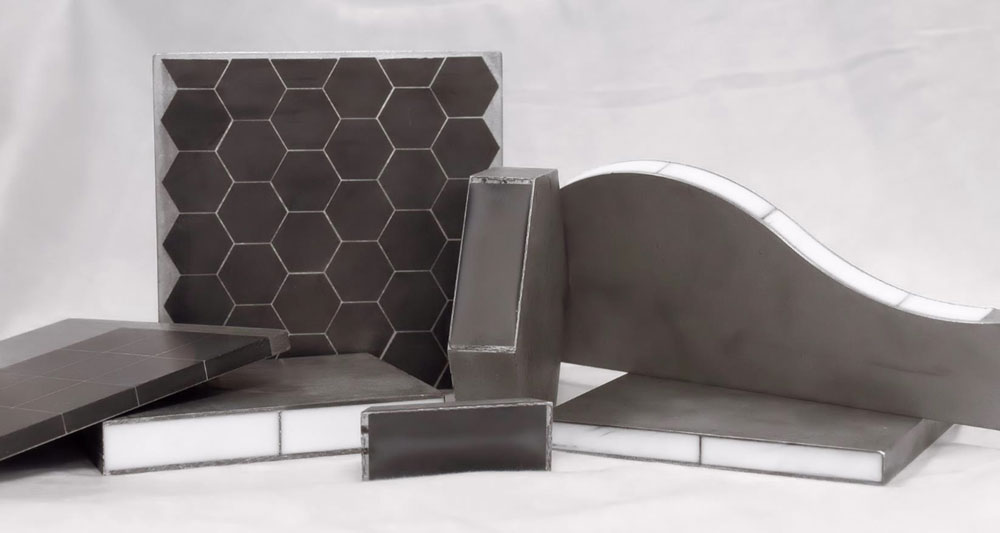

So, what’s the CPS solution? For the U.S. Navy and many others, it’s our proprietary HybridTech Armor® panels.

Less Weight, More Functionality with HybridTech Armor®

HybridTech Armor® is an innovative application of metal matrix composites that exemplifies a significant advancement in protective solutions. Our cutting-edge armor system combines the strength of traditional ballistic materials with the enhanced performance and lightweight characteristics offered by MMCs.

“The biggest selling point we have for our HybridTech Armor® is that it offers an equivalent level of protection as high hard steel, but it’s half the weight and is very environmentally durable,” says Joe Englin, Senior Business Development Manager for CPS.

HybridTech Armor® also demonstrates exceptional resistance to environmental conditions, including corrosion and wear, making it highly durable and suitable for prolonged deployments in various terrains and climates without the need for constant, costly maintenance mid-deployment.

Global Innovation at CPS Technologies

Ready to discuss your MMC design needs?

CPS offers a suite of innovative solutions to give clients complete peace of mind in their solution. With our state-of-the-art AlSiC composite, proprietary machining processes, and time-tested expertise, we’ll show you why CPS is a trusted partner in the industry.

More Advantages of HybridTech Armor®

Some advantages of HybridTech Armor®, an advanced MMC product, over something like traditional steel armor have already been mentioned, but these advantages go beyond weight savings.

Application and operational advantages of HybridTech Armor® include:

- Size – HybridTech Armor® offers a thinner profile which optimizes the utilization of space within military vehicles and allows for more efficient integration of other systems and payloads.

- Weight – HybridTech Armor® provides a significant reduction in weight which improves mobility, fuel efficiency, and overall vehicle maneuverability to enable enhanced operational effectiveness in diverse terrains and combat scenarios.

- Performance – HybridTech Armor® exhibits enhanced ballistic resistance and protection capabilities thanks to the incorporation of MMCs which translates into superior survivability and increased defense against armor-piercing projectiles and explosive threats.

- Cost – HybridTech Armor® may involve a higher upfront investment, but it offers long-term lifecycle cost savings. The durability of MMC-based armor systems contributes to an extended lifespan, reduced maintenance requirements, and weight reduction which decreases logistical expenses.

The advantages in size, weight, performance, and cost-effectiveness of HybridTech Armor® make it a compelling choice for military applications.

Choose CPS for Advanced Military Metal Matrix Composite Solutions

CPS Technologies’ HybridTech Armor® represents a significant advancement in military armor technology. The in-the-field combination of lightweight design, superior protection, thermal management capabilities, durability, and more continues to push the boundaries of modern defense applications.

That’s why industry-leading partners continue to choose CPS for their metal matrix composite solutions.

Want to learn more about how CPS Technologies and our MMCs can enhance your operational capabilities? Contact our material specialists today!