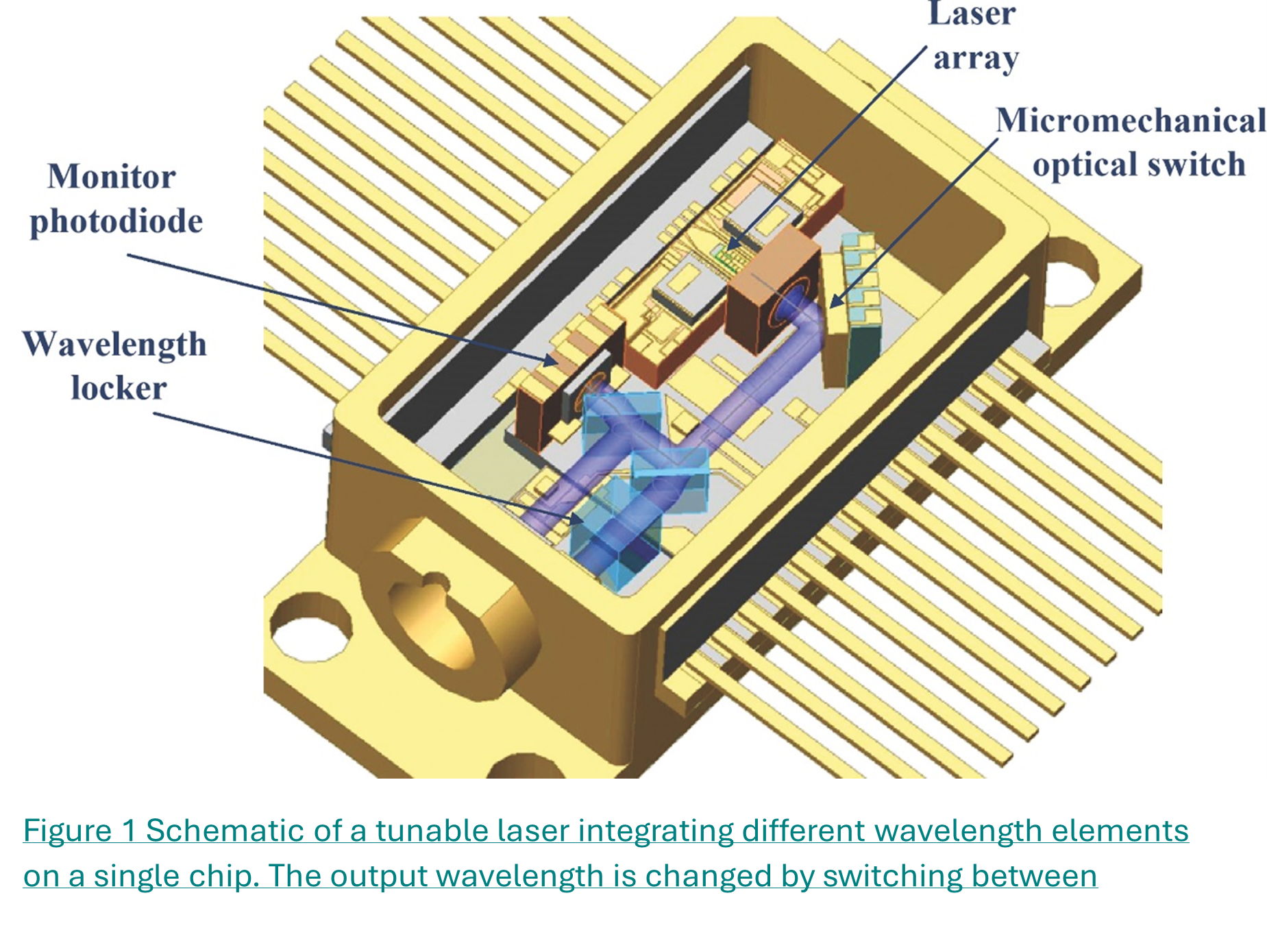

Optical and laser systems are being employed in an ever-increasing number of projects around the world, ranging from detecting methane from space, materials processing, medical and analytical systems, and potentially transmuting nuclear waste. For reliable performance, optical systems must be assembled on a substrate or optical bench which has known and predictable thermal performance, while also providing a structure that is tolerant to shock and vibration.

CPS Technologies’ metal matrix composites (MMCs) provide an ideal set of properties for these systems. CPS MMCs are lightweight and high stiffness, with a high capacity for thermal dissipation and a known, low coefficient of thermal expansion. CPS MMCs are ideal for weight sensitive applications, enabling a next generation of both small and large optical systems.

CPS Metal Matrix Composite Benefits

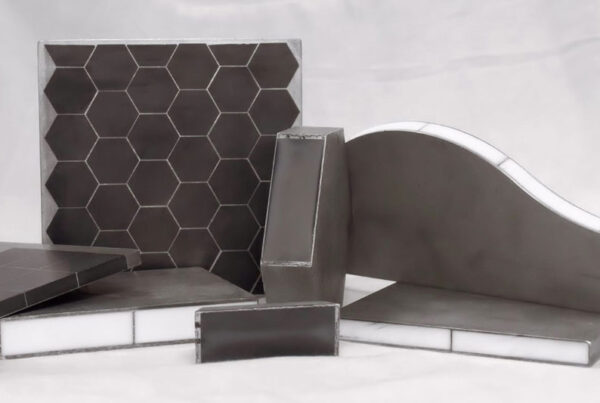

Optical benches are deployed in a variety of rugged environments, requiring a number of unique physical and thermal properties for optimal performance that are not often met by traditional alloys and ceramics. By reinforcing a continuous metal matrix with ceramic particles, CPS Technologies creates composites with truly unique thermal and mechanical performance.

Some of these benefits include:

- Controlled Thermal Expansion– Controlled, predictable thermal expansion eliminates the need for mechanical, electrical, or programming compensation, simplifying construction, improving reliability, and increasing system functionality.

- Coefficient of Thermal Expansion– MMCs have device-compatible thermal expansion coefficients, allowing direct attachment of laser diode submounts for improved thermal dissipation. Thermal electric coolers (TEC) used in pulse laser diode systems can also be soldered directly to an MMC optical bench, as the CTE is compatible with the TEC material construction, resulting in improved reliability.

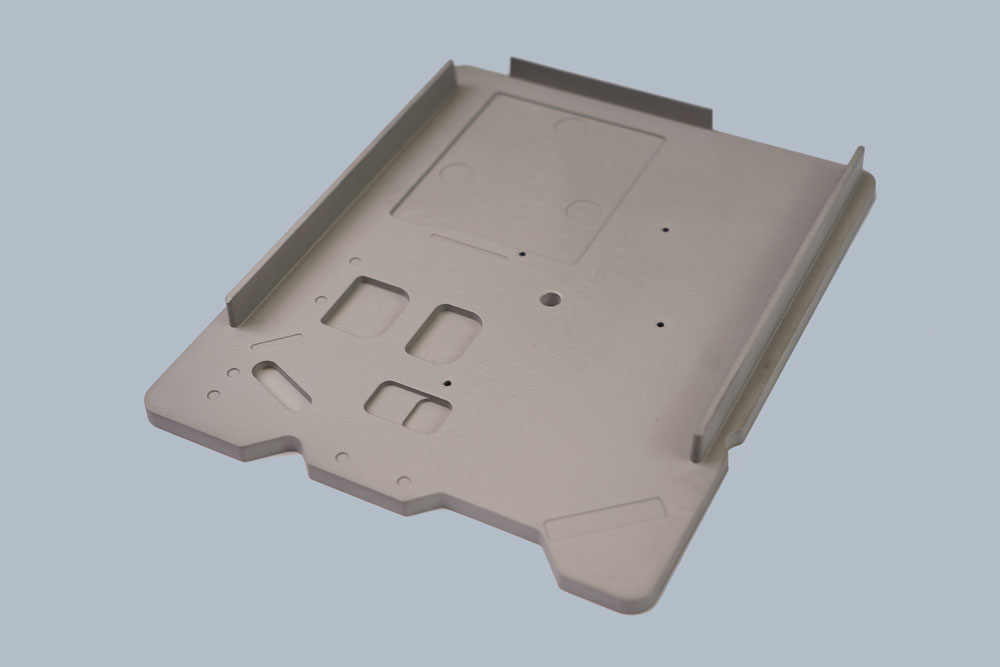

- Lightweight and high strength– MMCs offer a unique combination of low density and high strength. While keeping weight down, our MMCs retain structural integrity, ensuring optical systems maintain functionality over the duration of your project. MMC systems are 1/3 lighter than traditional alloy optical bench systems, allowing them to be employed in weight-sensitive applications such as aerospace structures and satellite.

- Strength/Stiffness– The high stiffness of MMCs improves the alignment of optical systems, improving system performance by reducing the influence of external vibrations.

- Ease of manufacturing – Cast as net-shape-products, our MMCs can incorporate functional features such as cavities, tabs, and holes without machining.

With the flexibility and benefits provided by our MMCs, CPS Technologies can make an optical bench to fit your needs.

Global Innovation at CPS Technologies

Ready to discuss your MMC design needs?

CPS offers a suite of innovative solutions to give clients complete peace of mind in their solution. With our state-of-the-art AlSiC composite, proprietary machining processes, and time-tested expertise, we’ll show you why CPS is a trusted partner in the industry.

Customers Around the World Turn to CPS for their Optical Benches

Want to learn more about our optical benches and other MMC products? Contact our team today to learn more about how CPS Technologies can use composite materials to change how you do business!