Immeasurable success comes from an invaluable workforce.

We Are Our People

Many modern manufacturers promise a cut-and-paste product, and that is okay. It’s easy to promise results when people and parts are interchangeable.

At CPS, our success stems from the immeasurable impact of our workforce. We are able to create custom, enterprise-level products, and components thanks to the exceptional people behind the process.

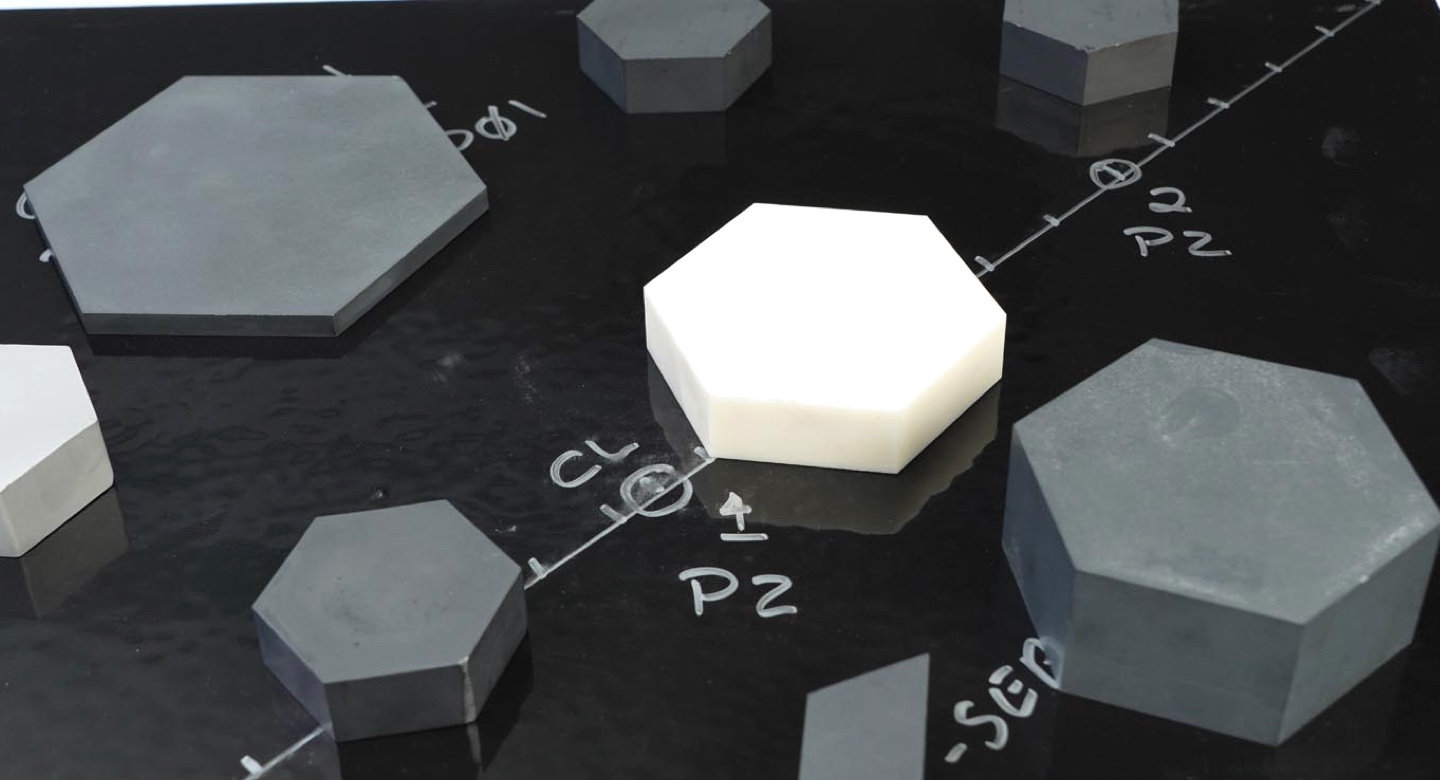

Innovation

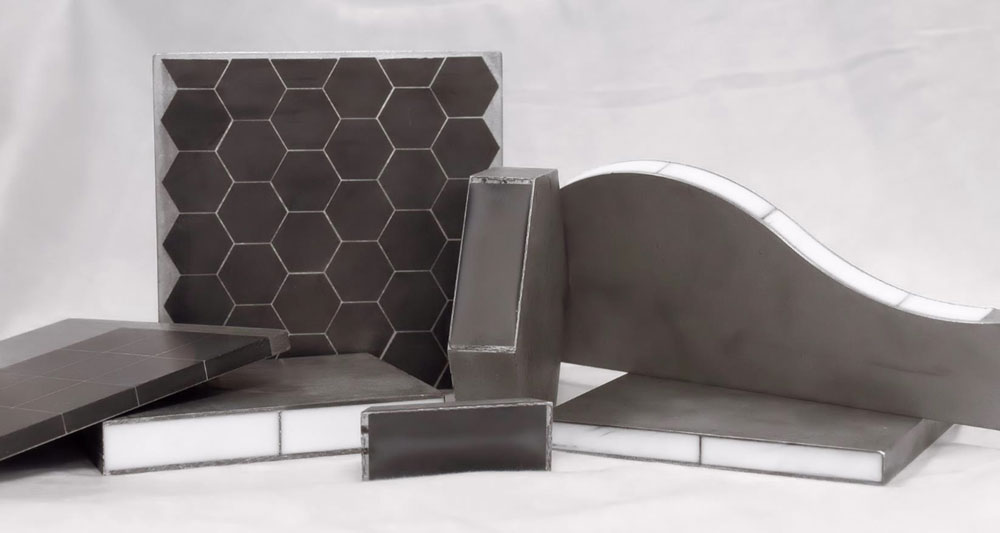

CPS is a world leader in metal matrix and ceramic composites. We continue to innovate and accelerate market megatrends to drive industry customization.

Teams, Not Individuals

We work together to create customized modern material solutions. No one person can deliver world-leading metal matrix and ceramic products and components. It takes teamwork to develop solutions our clients trust.

Room for Growth

Our markets are large and growing — and our competition is limited. Only a few companies in the world can make high quality metal matrix composites.

CPS’ technology is a strong, proprietary process for combining metals and ceramics. This is supported by an experienced and capable management team who ensures we’re always moving forward.

Looking to the Future

No industry stays the same forever. With economic and climate uncertainty comes a need to focus on the future. CPS experts and composite engineers work to bring innovative new materials and material solutions to clients who need them.

Transform the World With Us

We are on a mission to change the world — and we need your help! We are always seeking bright minds who share our vision for the future. If you are eager to make your mark on the world, check out our available positions to see where you fit in!

Manufacturing Engineer Co-op/Intern

Duration

3-6 Months

Location

Norton, MA

Mission

CPS is a world-leader in developing advanced materials solutions for transportation, energy, aviation, defense, and oil & gas industries.

Our advanced metal matrix composites offer superior benefits compared to traditional materials and give our customers complete confidence in product performance and reliability.

Description

We are looking for a talented, driven engineering student with an interest in 3d printing, ceramics, metal matrix manufacturing, and/or building and scaling production lines may be a good fit. You will be part of a small team and find that your day-to-day tasks actively contribute to our company’s success. Our ideal teammate communicates effectively, is process and data-driven, works well under pressure, and is eager to learn. As a Manufacturing Engineer Co-op/Intern, your primary customer will be our manufacturing technicians. This may include projects related to improving part transport, sourcing the right solution for our application, quality control, and root cause analysis to name a few! You will become intimately familiar with our production workflow allowing you to drive high level improvements to the manufacturing process.

Essential Duties and Responsibilities

- Address CAPA’s via root cause analysis and design of experiments

- Employ 5S and lean manufacturing techniques

- Ensure that the best solutions (processes, machines, tools) are being employed within our production line

- Perform process workflow simulations, risk assessments, and process change validation documentation

- Ability to design and test jigs and other aids to support productivity and performance

- Support production team by troubleshooting issues

Education

- In-Progress Bachelor’s degree in Engineering or Engineering Technology

Skills

- Interest in manufacturing methods and procedures and process development

- Interest in developing risk-based thinking, failure analysis, design of experiments, and root cause analysis skills

- Self-motivated, data-driven, eager to learn, excellent organizational skills, comfortable working in a fast-paced environment

- Analytical thinker

- Strong verbal and written communication/documentation skills

- Interest in controls systems and automation.