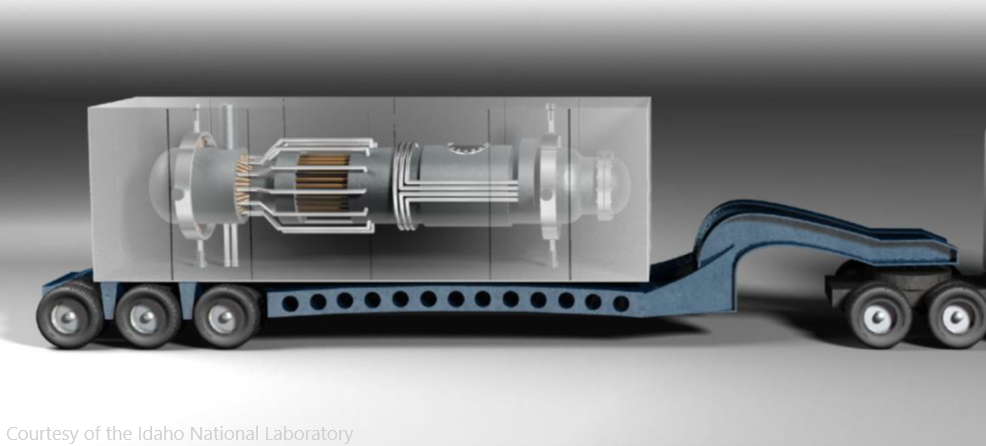

Nuclear energy is critical to curtailing climate change and achieving a carbon-neutral future. Advanced nuclear reactor concepts are rapidly progressing through design stages, and their testing, fabrication, and deployment are becoming more realistic by the day. Small Modular Reactors (SMRs) and Microreactors have been designed to reduce the cost and manufacturing burdens associated with traditional Generation II and III reactors. Microreactors are a discrete departure from typical designs, intended to be rapidly deployed to remote locations such as rural communities, mining sites, military installations, and disaster relief zones, delivering safe, clean, and reliable energy. Because they are designed to be portable, agile and rapid microreactor deployment is reliant on driving down the mass of reactor support systems, such as radiation shielding, while still providing optimal performance.

Traditional Materials Used in Radiation Shielding

Gamma and Neutron radiation must be moderated to ensure safe reactor operation. Gamma rays are easily absorbed by high-atomic number particles such as lead, or very large volumes of less dense materials such as water, steel, or concrete. Neutrons are absorbed through interactions with lower atomic number materials such as boron, carbon, or hydrogen.

For large-scale reactors, massive volumes of water and concrete knock down radiation levels, but SMRs and mobile microreactors require more elegant solutions. Designing radiation shielding materials that can combine gamma and neutron attenuating constituents has the potential to drive down overall system mass and simplify designs. By advancing radiation shielding to be more compact and lower density, project weight budgets can be redirected to allow for efficient reactor construction, deployment, and operation.

CPS’ Modular Radiation Shielding

CPS is developing advanced composite radiation shielding to support microreactor transport and operations. By combining high-density gamma shielding constituents and low-density neutron absorbers in an aluminum matrix with our QuickSet™ Injection Molding system, CPS is able to create customizable radiation shielding composites for both gamma and neutron shielding in a single envelope. The aluminum matrix serves to provide significant lightweighting, while still having up to 60% volume of radiation blocking elements. QIM is compatible with any metal (stainless steels, Inconel, tungsten, and others) or ceramic (silicon carbide, boron carbide, alumina, and others). By creating multimaterial preforms and infiltrating them with aluminum, CPS creates a fully dense MMC.

Two examples of CPS’ radiation shielding MMCs and their performance when exposed to gamma radiation (a Co60 source) are shown below. The composites utilize blends of tungsten and boron carbide to simultaneously provide neutron and gamma shielding. The Half-Value-Layer (HVL) represents the thickness of material required to halve the intensity gamma radiation. HVL values for the MMC components are similar to those of steel, lead, and tungsten, but because CPS MMCs have much lower density than these materials, yield a much lighter solution.

Given an equal cross-sectional area, the “Half-Value-Mass” of each material can be calculated. In this case, assuming a 1 cm2 area, MMC solutions are 50-60% lighter than other materials.

| Material | Co60 HVL (mm) | Density

(g/cc) |

Half-Value Mass

(g) |

| Concrete | 60.5 | 2.5 | 15.125 |

| Steel | 21.6 | 8 | 17.28 |

| Lead | 12.5 | 11.34 | 14.175 |

| Tungsten | 7.9 | 19.3 | 15.247 |

| Uranium | 6.9 | 19.05 | 13.1445 |

| Al-W-B4C MMC1 | 15 | 4.1 | 6.15 |

| Al-W-B4C MMC2 | 9 | 6.7 | 6.03 |

By decreasing mass, CPS ensures microreactors can be transported wherever they are needed most without sacrificing the safety of the people around them. CPS continues to actively research improvements to these materials including further lightweighting, engineered neutron and gamma attenuation properties, and development of large-scale manufacturing.

Global Innovation at CPS Technologies

Ready to discuss your MMC design needs?

CPS offers a suite of innovative solutions to give clients complete peace of mind in their solution. With our state-of-the-art AlSiC composite, proprietary machining processes, and time-tested expertise, we’ll show you why CPS is a trusted partner in the industry.

Customers Around the World Turn to CPS for their MMC Needs

Want to learn more about radiation shielding and other MMC products? Contact our team today to learn more about how CPS Technologies can use composite materials to change how you do business!