Across the world, we are seeing a greater need for quickly and easily deployed power delivery systems. In remote parts of the world where traditional power grids cannot reach, or areas whose power grids fail, new systems must be deployed to avoid disruptions. To address this, more countries are turning to renewable energy and utility-scale batteries.

Quick Deployment After Disaster

When Hurricane Helene hit the American southeast, it was estimated more than three million people were left without power. To assist some of those in the region, people turned to solar power and batteries. These “microgrids” were used to power community centers, water pumps, and other necessities for those going through disaster.

Even less devastating natural disasters, such as winter storms that have impacted the power grid in Texas, can be life or death without an adequate power supply. In these situations, traditional power delivery systems have failed time and time again, proving the need for a different solution.

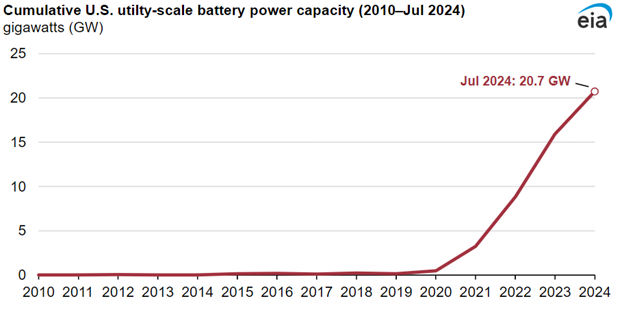

A Growing Industry

Many governments are already planning the future of their power grid for the next disruption. In the past four years, for example, the United States has installed 20 gigawatt of battery capacity to its power grid. For comparison, U.S. nuclear power plants produce about 1 GW of power per plant.

However, the International Energy Agency says this is not enough, indicating 80,000,000 km of grids must be replaced or added by 2040 to meet targets. Adding this infrastructure is not an easy task and will require a large amount of resources.

Advantages of Metal Matrix Composites in Updating Our Power Grid

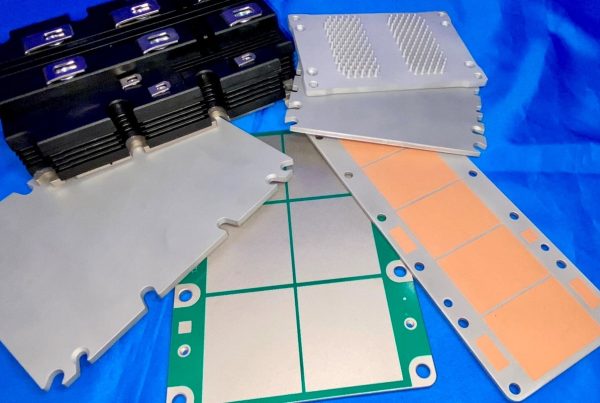

While updating power grids to meet climate targets and avoid the drawbacks of traditional methods, MMCs, particularly Aluminum silicon carbide (AlSiC) composites, are an ideal partner in this effort.

MMC benefits for energy applications include but are not limited to:

- Enhanced heat dissipation: Efficient heat dissipation is crucial for electrical devices’ reliable and continuous operation. MMCs like AlSiC composites offer superior thermal management capabilities. Their high thermal conductivity enables effective heat transfer, which helps prevent overheating and maximizes system performance. Whether solar panels, wind turbine generators, or power electronics, MMCs contribute to improved heat dissipation.

- Improved Thermal Management: The AlSiC MMC thermal management combines high thermal conductivity and a compatible thermal expansion to the assembled substrates and electronic components to maintain efficient heat dissipation for long-term power electronics reliability.

- Lightweight and high strength: Renewable energy systems often require lightweight materials to simplify transportation, installation, and operation processes. MMCs offer a unique combination of low density and high strength. The overall weight of components is reduced without compromising structural integrity when MMCs are incorporated. This leads to cost savings, more manageable logistics, and improved system performance.

- Corrosion resistance and longevity: Renewable energy systems are often exposed to harsh environmental conditions, including moisture, salt, and extreme temperature fluctuations. MMCs exhibit excellent corrosion resistance and ensure prolonged durability and reliability in challenging environments.

Companies can enhance the lifespan of their renewable energy infrastructure, reduce maintenance costs, and maximize return on investment when they utilize MMCs in critical components like offshore wind turbine foundations or utility scale batteries.

Global Innovation at CPS Technologies

Ready to discuss your MMC design needs?

CPS offers a suite of innovative solutions to give clients complete peace of mind in their solution. With our state-of-the-art AlSiC composite, proprietary machining processes, and time-tested expertise, we’ll show you why CPS is a trusted partner in the industry.

CPS Technologies is the Ideal Partner for the Future of Energy

CPS Technologies is a trusted industry leader in metal matrix composites due partly to a long history of successful, innovative solutions. Decades of experience compels our MMC specialists to perfect the formulation of our composites and continue demonstrating their efficacy across various industries.

With CPS Technologies as a partner, you can leverage our extensive expertise and knowledge to drive innovation in the renewable energy industry. Contact a metal matrix composite specialist today to get started!