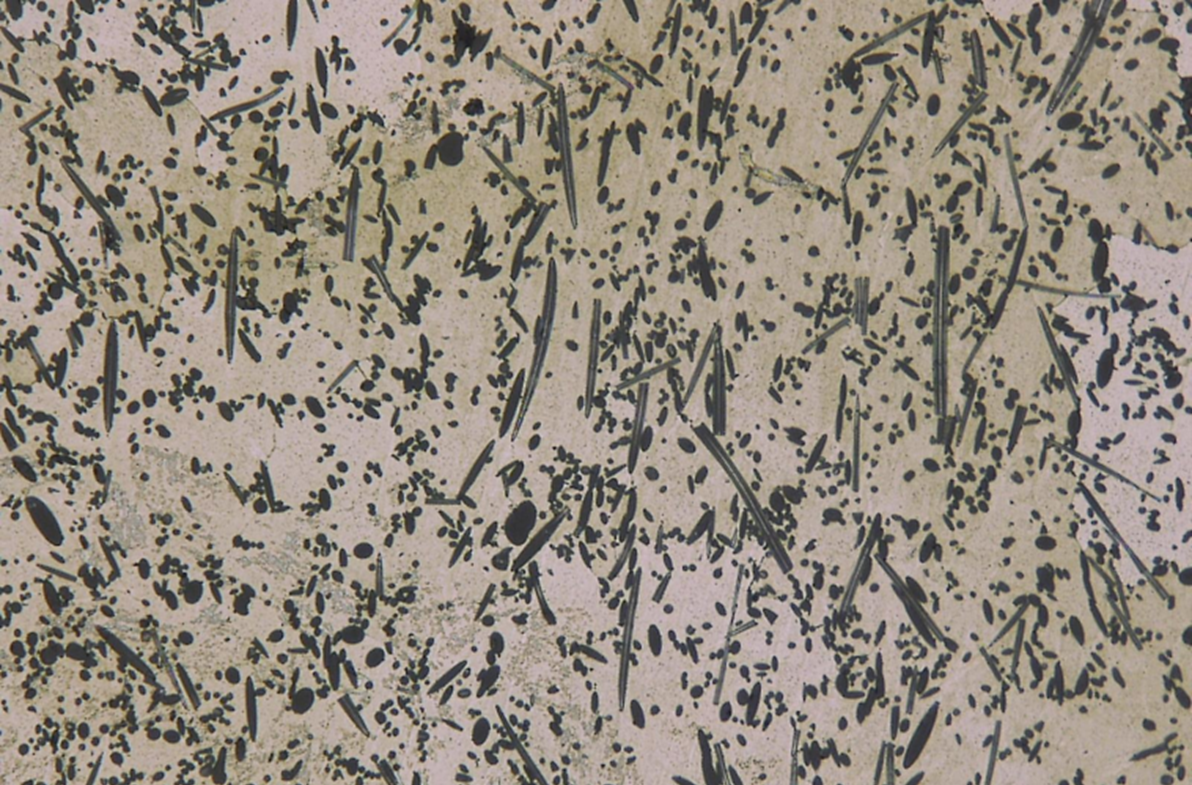

Created by combining discontinuous ceramic fibers and aluminum, Fiber Reinforced Aluminum™ (FRA) metal matrix composite materials offer improved mechanical and wear performance over traditional alloys and composites. The benefits of FRA manufactured by CPS lends itself to a multitude of both military and commercial applications, creating a stronger, more reliable product.

Benefits of Fiber Reinforced Aluminum™

Combining 25 volume percent or greater ceramic fibers and high strength aluminum in FRA improves performance over traditional alloys. Benefits include:

- Sustained mechanical performance above 400°F: FRA keeps performing in harsh environments by maintaining 3x the strength of conventional aluminum alloys at elevated temperatures. FRA maintains a tensile modulus of 83 Gpa at 400°F, allowing it to be implemented in thermomechanical systems where traditional Al alloys can not be considered.

- Improved wear resistance: While operating at higher temperatures, FRA also shows an increased durability over time. Fiber Reinforced Aluminum™ has a 200% improved wear resistance compared to steel or cast iron.

- Low density: Traditional alloys can be too heavy for some applications and requires a tradeoff between performance and weight. FRA maintains a density 1/3 that of steel (2.96 g/mc3 ) while providing improved wear performance compared to steel and increased mechanical properties compared to aluminum alloys.

FRA Applications

Military Applications

Militaries around the world operate in the harshest environments, where reliability and strength are paramount. During operations, repairs are not an option, and the smallest of mechanical failures can end any chance of success.

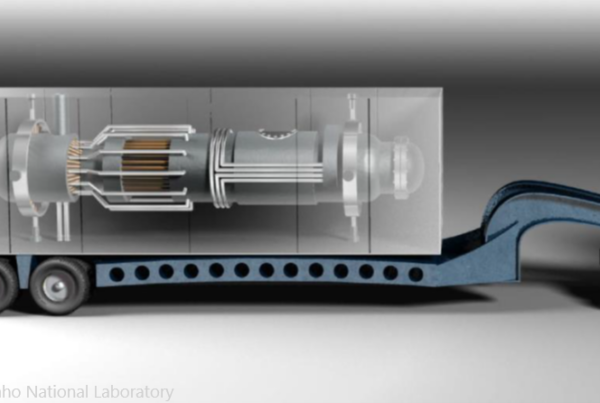

Whether it be surveillance missions, dogfights, or troop transports, it is vital soldiers can depend on the reliability of their equipment. FRA reduces wear of components, allowing them to last longer with less maintenance compared to traditional materials. Additionally, FRA improves Size, Weight, and Power (SWAP) of equipment due to decreased density (1/3 that of steel) and improved mechanical and wear properties. Integral components such as bushings, liners, and pistons can be created with FRA for improved performance, fuel savings, and life of components.

Commercial Application

The benefits of FRA easily translate to commercial industries, ranging from aerospace, motor sports, transportation, and oil drilling. Whether you’re flying from Singapore to New York, making the final turn in the 24 Hours of Le Mans, or drilling for the oil that makes the world turn, reliable mechanics are a necessity.

Global Innovation at CPS Technologies

Ready to discuss your MMC design needs?

CPS offers a suite of innovative solutions to give clients complete peace of mind in their solution. With our state-of-the-art AlSiC composite, proprietary machining processes, and time-tested expertise, we’ll show you why CPS is a trusted partner in the industry.

Customers Around the World Turn to CPS for their Fiber Reinforced Aluminum™

CPS Technologies Corp. holds the exclusive rights to manufacture and sell products using Triton’s FRA composite technology. Want to learn more? Contact our team today to learn more about how CPS Technologies can use fiber reinforced aluminum to change how you do business!