Space exploration is a costly endeavor, with budgets ranging from hundreds of millions to upwards of billions of dollars. While thousands of miles from earth, repairs are out of the question, and a minor issue can cause the end of any project. With this in mind, more and more space agencies are turning to CPS Technologies for their hermetic packaging needs.

What is a Hermetic Package?

Hermetic packaging (HP) simply refers to a package with an airtight seal. This prevents gasses and other harmful materials, such as dust on Mars, from damaging electrical components.

Materials Used in Hermetic Packaging

Standard copper (Cu) and aluminum (Al) alloys can be used in hermetic packaging, as they are cheap and easily machined, but high coefficients of thermal expansions (17 and 23 ppm/°C, respectively) limit their reliability. This is where composite materials come into play.

Since the 1930’s, copper-molybdenum (CuMo) and copper-tungsten (CuW) have been utilized as “thermal management” materials. By combining properties from both materials, end-users can achieve high thermal conductivity with controlled thermal expansion to match electronic components. These composite materials still have drawbacks:

- Weight– Once something leaves Earth’s gravity, weight is not a major concern, but driving down launch weights, and therefore costs, is still critical. CuMo and CuW are both high density (10-17 g/cm3). These materials must be used sparingly in weight-sensitive applications, such as aerospace or mast

- Difficult to manufacture– Manufacturing CuMo and CuW is very complex. While sheets and billet stock can be stamped, complex shapes must be machined. The inclusion of refractory metals (Mo, W) in soft Cu makes this a costly and time consuming process.

- Cost– CuMo and CuW are very expensive materials without machining. Machining operations themselves are costly. Factoring in waste during machining of complex shapes makes widespread adoption cost prohibitive.

CPS Technologies’ AlSiC hermetic packaging is a superior alternative to traditional alloys and other composite materials.

The Benefits of AlSiC Hermetic Packaging

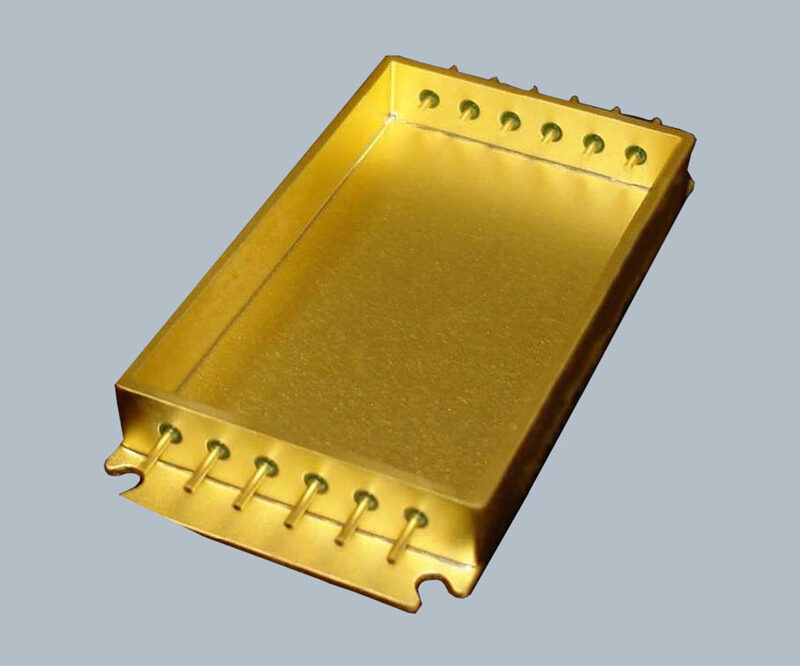

Aluminum Silicon Carbide (AlSiC) is a metal matrix composite (MMC) used in thermal management applications since 1990 and has been a viable hermetic package solution since 2016. AlSiC has a high thermal conductivity (180 W/m-K minimum) and a low, device and substrate-compatible, CTE (7.4 ppm/°C. These thermal characteristics, coupled with a high-strength that reduces shock during launch, travel, and re-entry, protecting sensitive electronics, make AlSiC an ideal hermetic packaging material.

Additional benefits include:

- Lightweight– AlSiC baseplates (3 g/cm3) are 40-60% less dense than CuMo and CuW. On airborne applications, every ounce matters. By utilizing a lighter material, weight budget can used for to other functional applications.

- Strength/Stiffness- An added benefit of AlSiC’s lightweight is a low inertial resistance. This improves shock and vibration tolerance, further reducing potential damage to key electronic components.

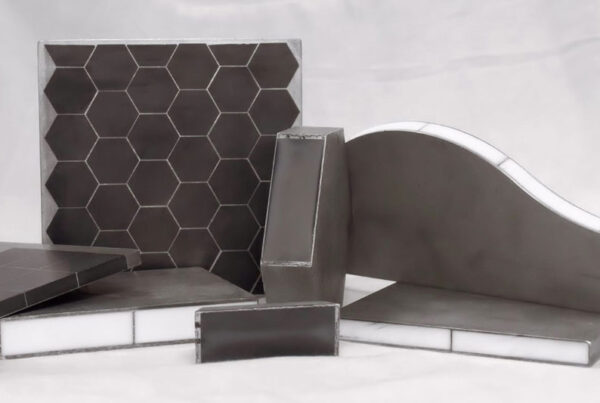

- Ease of Manufacturing- AlSiC baseplates are cast as net-shape-products, meaning functional features such as cavities, tabs, and holes can be incorporated without machining. AlSiC also supports, nickel (Ni), and nickel-gold (Ni-Au), and other plating schemes typically used in hermetic packaging.

- Cost- AlSiC’s fabrication process allows hundreds of components to be produced simultaneously, driving down production costs compared to traditional hermetic packaging materials.

Global Innovation at CPS Technologies

Ready to discuss your hermetic packaging design needs?

CPS offers a suite of innovative solutions to give clients complete peace of mind in their solution. With our state-of-the-art AlSiC composite, proprietary machining processes, and time-tested expertise, we’ll show you why CPS is a trusted partner in the industry.

Customers Around the World Turn to CPS for their Hermetic Packaging Needs

As space agencies continue to explore the universe around us, they do not want to worry about an electrical failure prohibiting our drive to explore. To avoid this, they turn to CPS Technologies’ expertise and experience in the HP field.

Want to learn more about our hermetic packaging line? Contact our team today to learn more about how CPS Technologies can use AlSiC composites to change the way you do business!