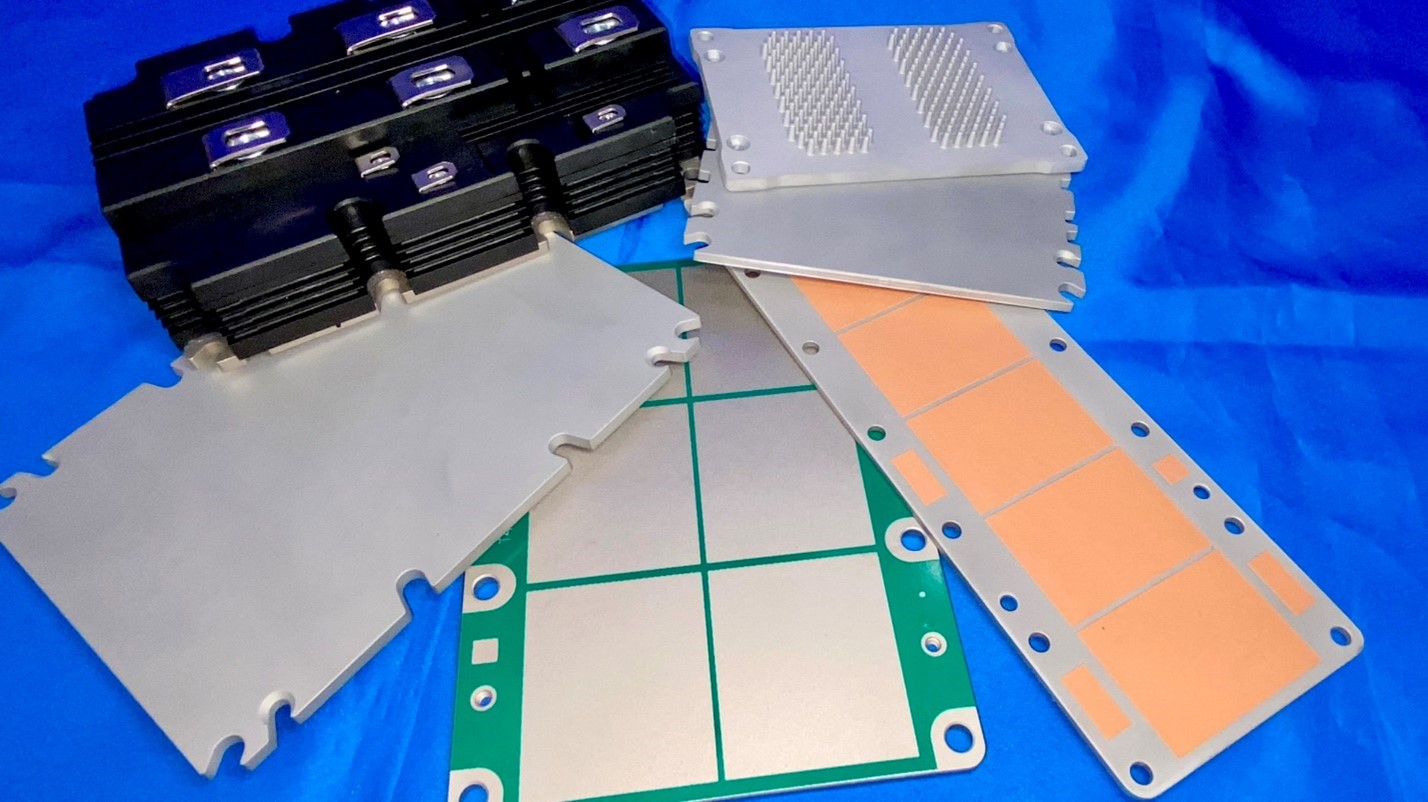

CPS Technologies is an international leader in advanced thermal management solutions for power electronics. Our expertise is working with metal matrix composites (MMCs), where we combine ceramic particles into a continuous metal matrix to achieve a new and intermediate set of properties not found in nature that solve unique property requirements. These composites offer our clients unique combinations of high thermal conductivity, heat dissipation, and thermal expansion, while being lightweight and having high mechanical strength.

These properties make our various MMCs highly sought after in various industries. Still, our aluminum silicon carbide (AlSiC) composites solve modern thermal management application challenges. The benefits of our AlSiC composites and the broad benefits of MMCs make them invaluable to aerospace, avionics, and complex power electronics systems.

AlSiC MMC Thermal Management for Power Electronics Performance and Reliability

Benefits of AlSiC MMCs in Thermal Management

CPS Technologies’ material scientists are experts in developing and manufacturing AlSiC composites.

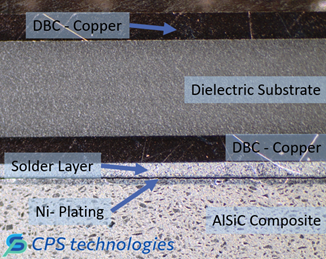

Aluminum alloy reinforced with silicon carbide particles, a key component of AlSiC composite materials, might not be a new technology. That said, our CPS AlSiC offers exceptional thermal management properties, combining high thermal conductivity with device and electronic materials compatible with a low coefficient of thermal expansion (CTE). Therefore, CPS AlSiC composites manage thermal dissipation and thermal cycling in power electronics particularly well.

“Thermal cycling will increase the stress state of electronics if heat is not adequately dissipated and the CTEs between dissimilar materials are not managed. That’s the big determinant there,” says Mark Occhionero, Senior Scientist at CPS. “We don’t want to cause delamination or crack the substrates and electronics because that would interrupt the thermal path, causing catastrophic device failure.”

Occhionero explains that an AlSiC system may improve the thermal dissipation performance of power module assemblies since the thermal path and interfaces may be reduced over copper, all other things being equal.

Product design is another key attribute for good thermal dissipation. Design solutions must include the influences of all assembled materials and their assembly process to provide a design that will interface completely, without gaps, with the heat-sinking system. CPS works with customers to provide initial designs and to help optimize design and performance throughout the product life cycle as manufacturing and process improvements are made.

Advantages of AlSiC Composites Over Traditional Systems

CPS Technologies’ AlSiC composites offer several advantages over traditional materials. The high thermal conductivity of our composites facilitates efficient heat dissipation, it enables better thermal management, and it increases power density in power electronics systems.

Furthermore, the lightweight nature of AlSiC composites (combined with the inherent benefits of MMCs) ensures reduced system weight and improved overall energy efficiency.

CPS AlSiC advantages also include:

- Superior thermal management – AlSiC composites possess excellent thermal conductivity, enabling efficient heat dissipation and thermal management in electronic devices, heat sinks, and power systems. This is crucial to prevent overheating and ensures the longevity and reliability of components.

- Reduced thermal expansion mismatch – AlSiC composites with low thermal expansion coefficients help alleviate the mismatch between different materials in composite structures. This enhancement is especially important in applications like electronic packaging and power electronics in which thermal expansion mismatches can lead to mechanical stresses and failures.

With these advantages, AlSiC composites:

- Lower thermally-induced stresses to improve reliability

- Allow direct device attachment for improved thermal dissipation

- Improve performance and reliability

Overcoming Challenges in Power Electronics with AlSiC Technology

CTE, Delamination, and High-Cycle Systems

CPS’s AlSiC Coefficient of Thermal Expansion is also highly compatible with electronic systems.

The low CTE of our AlSiC composites helps mitigate the mismatch between different materials in power electronics systems. This is crucial when high-temperature variation thermal cycling can lead to catastrophic mechanical stresses, structural deformations, and even failure of critical components.

Moreover, high-cycle systems prone to delamination—where a traditional copper base plate might experience delamination after 4,000 thermal cycles—see constant thermal dissipation without damage to the solder surface thanks to CPS’s AlSiC base plates.

“When you delaminate at the interface, you narrow the area for thermal dissipation,” says Occhionero. “It’s no longer connected, and the electronics and system exhibit thermal runaway. The electronics will run hotter and may be damaged, the assembly exhibits further delamination to the point where you have a failure of the entire system.”

The reliability provided by CPS AlSiC composites keeps our clients coming back for thermal management solutions, whether they’re on the ground or circling the planet.

Global Innovation at CPS Technologies

Ready to discuss your MMC design needs?

CPS offers a suite of innovative solutions to give clients complete peace of mind in their solution. With our state-of-the-art AlSiC composite, proprietary machining processes, and time-tested expertise, we’ll show you why CPS is a trusted partner in the industry.

Clients Around the World Trust CPS for AlSiC Composites

It’s not just on-the-ground electrical systems that benefit from our proprietary AlSiC composites. Our MMC solutions went with the Perseverance rover to Mars and will ride a MethaneSAT satellite as it circles Earth in the near future.

These kinds of applications and more compel material scientists like Occhionero to enhance our MMCs further.

“Our competition likes to sell one-size-fits-all,” he says candidly. “CPS designs products that specifically meet our customers’ performance and design needs to improve assembly and thermal performance.”

Want to learn more about our metal matrix composites? Contact our team today to learn more about how CPS Technologies can use AlSiC composites to change the way you do business!